Painting the Engine

Tools and Materials Used

- Mr Surfacer 1200 primer

- Alclad II Steel

- Alclad II Aluminium

- Vallejo Model Color 70.950 Black

- Vallejo Model Color 70.820 Offwhite

- Vallejo Model Color 70.871 Leather brown

- AK-086 Dark Steel pigment

- AK-043 Medium Rust pigment

- Citadel color Boltgun Metal

- Citadel color Mephiston Red

- Black oil colour

- Thin round brush

- Old ruffled thin brush

- White Spirit

The engine is first primed with Mr Surfacer 1200 applied with an airbrush. Once dry a thin layer of gloss black is applied to serve as a base coat for the subsequent application of Alclad II Steel.

The engine block was then painted using a thin mix of black and white Vallejo acrylics by brush. The thinned paint is slightly translucent leaving some of the metallic sheen underneath to show through. The exhaust stacks and most of the plumbing is not painted over.

|

Next, I apply some AK-086 Dark Steel pigment using an old brush. I apply the pigment to the areas between the engine detail avoiding the recesses to create a sense of depth. Using the same brush I apply some AK-043 Medium rust pigment to the exhaust stacks.

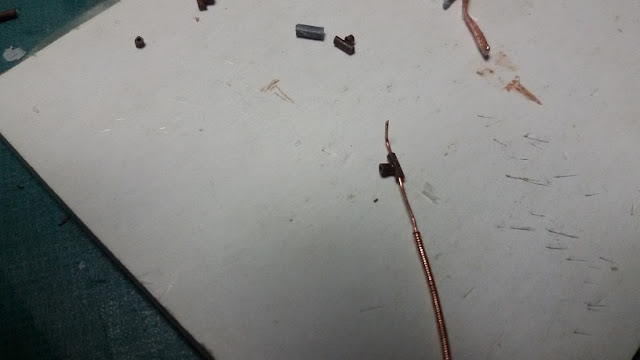

Plumbing and engine detail is picked off using Citadel Boltgun Metal

Some of the plumbing is painted with a red-brown mix using Citadel and Vallejo acrylics.

The engine brackets are primed using Mr Surfacer followed by some Gloss Black. They were then painted over using Alclad II Aluminium.

A black wash is obtained by diluting some black oil colour with white spirit. The wash was generously applied to the brackets.

After a few moments, the excess is wiped off using a paper towel.